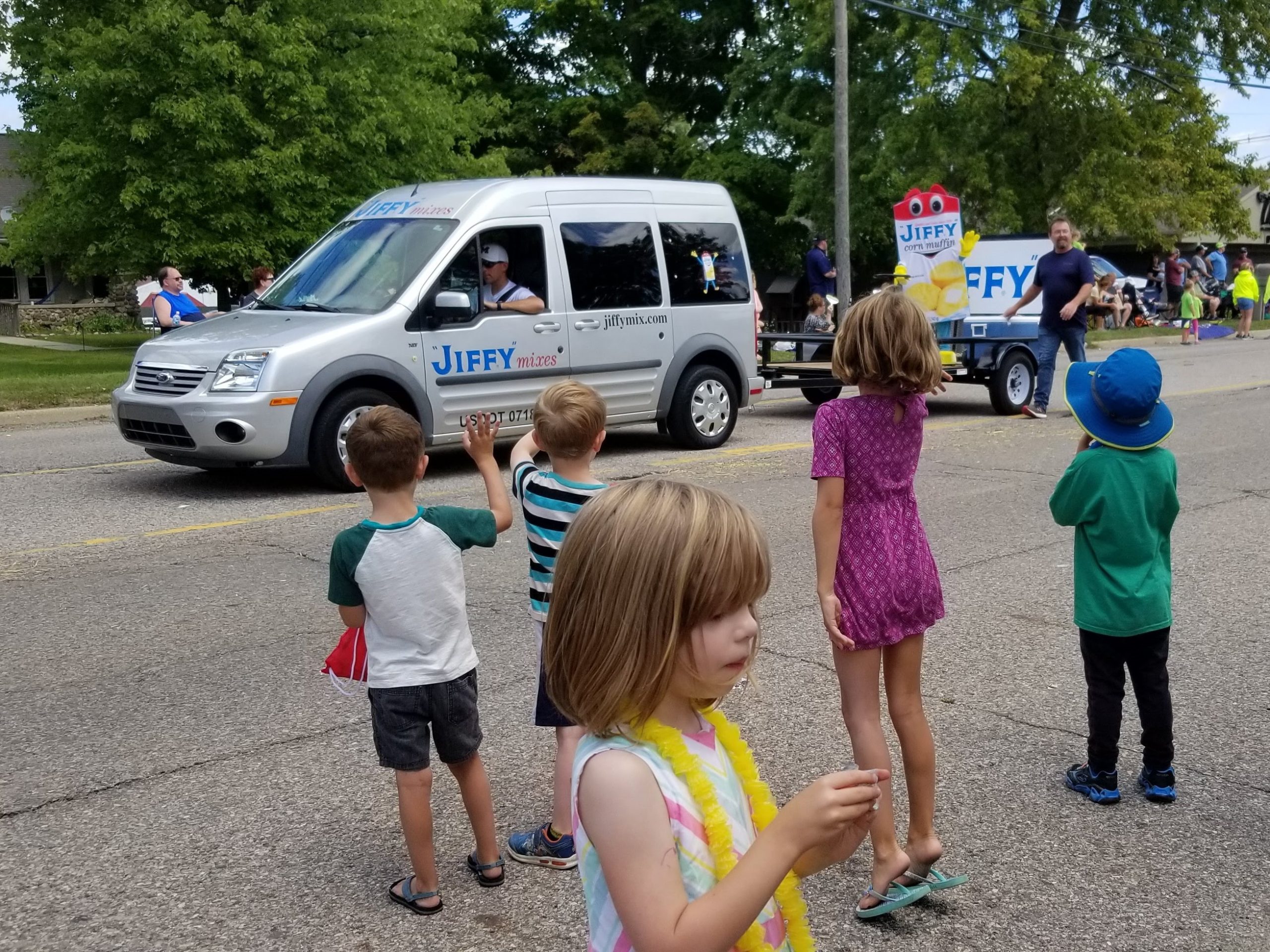

“Jiffy” Mix featured prominently in my childhood in Chelsea. Visually, of course, as the Chelsea Milling Co’s grain elevators loom over downtown, and also culturally: Jiffy factory tours were a regular elementary school field trip, and the annual Chelsea Fair Parade features their mascot Cornelius J. Box handing out corn muffin mix where other floats are throwing candy.

For places that have lost their flagship manufacturers, then, the loss is not just economic, but tears through the civic fabric. Beyond the loss of jobs and tax base, a plant closure or relocation may mean losing community groups’ donors or volunteers. Even if the manufacturing activity itself remains, a change of ownership and management from local to remote can trigger this pullback in civic involvement. While relocation subsidies can bring a new plant to town, they usually can’t rebuild this civic role—a manufacturer chasing subsidies as part of a ruthlessly efficient and hyper-lean strategy isn’t as likely to pay the wages or support the community institutions that a business grown up as part of the community is.

The crisis has also shown that making things remains a strength of our communities at all scales. Whether it’s craft distilleries converting their stock into hand sanitizer, small machine shops collaborating to 3D print plastic face masks, auto manufacturers ramping up ventilator production, or the thousands of individuals across the state sitting down to sew face masks at home, Michiganders are jumping in to fill the gaps—and showing how much creativity and willingness to roll up their sleeves our communities possess.

We should remember this when the current crisis is over. While a branch of a large multinational manufacturer can play a role in place, our economic development strategies also need to support those constellations of makers who can grow jobs by ones and twos—and who will grow solid roots in a place.

Cities, villages, and urban townships can work on scaling down business incentives to put them in reach of small shops; networking individual producers to the businesses that can sublet extra space or down time on their machinery; creating tool lending or timeshare at libraries or maker spaces; tapping local capital networks through investment crowdfunding; or enacting local procurement policies that use public purchasing to support business growth.

Not every community will end up home to the global leader in boxed corn muffin mix manufacturing, of course, but places that nurture their local ecosystems of people making things will build community wealth not just through economic benefits, but from the reinvestment in place by those people.

For more, check out:

- Brian Alexander’s Glass House chronicles in the story of Anchor Hocking’s acquisition by private equity firms.

- Our friends at Recast City offer “ideas to steal” on supporting small-scale manufacturing.